Internal thread Adaptor PE100 PN 16 fi 32x1 "mm

- Color

- Black

- Diameter

- 32x1

- Operating pressure

- 10 bar Gas/16 bar water

- Standard

- EN1555 and EN12201

- Types

- Polyethylene (PE HD)

- Apply

- PE HD Water Supply network

Have questions? We are here for you

High quality, attractive prices.

Don't wait, we process immediately.

Offer for everyone, delivery across Europe.

Electrofusion fittings

We offer electrofusion fittings made of black polyethylene stabilized with carbon. This material is the most popular and most commonly used in the construction of underground systems for the distribution of water and gas. It does not show any negative impact on food products and human physiology, which allows its presence in similar systems.

For the production of our fittings, we only use PE100 polyethylene with the highest flexibility and high abrasion resistance. Its use in the construction of municipal and industrial installations determines its advantages, i.e.

- High durability

- High abrasion resistance

- Low coefficient of friction

- Exceptional resistance to dynamic and chemical loads

- Ability to effectively damp vibrations

- Low specific weight

- Relatively high corrosion resistance

What is electrofusion welding?

Our polyethylene fittings are combined using electrofusion welding. The heating element of the fittings takes the form of coiled resistance wire. As a result of the current flowing through it, heat is generated, which results in an increase in the plasticity of the outer surface of the pipe and the inner surface of the fitting. Plastics penetrate each other, and when their temperature decreases, they acquire a uniform structure.

The use of an electrofusion connection caused our fittings to be extremely durable, also at the joints. Systems made in this way are characterized by low weight and high efficiency of operation. The process is fully automated, which translates into a lack of necessity to operate it.

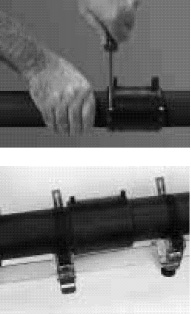

Step by step electrofusion welding

For electrofusion welding, a special machine is used, to which parameters of the manual fitting or using a code reader are entered (all parameters are placed on the bar code of the fitting). What is the process of electrofusion welding?

- We place the bare end of the pipe or fitting inside the electrofusion fitting

- We connect the machine ends with electrofusion fittings

- We enter the welding parameters

- Energy is transferred to the fitting

- The winding temperature increases

- The surface of the pipe and the material surrounding the winding become plasticized

- The materials merge homogeneously

Installation of electrofusion fittings

The packaging contains a fitting and a magnetic card. Fittings are ready for assembly, they do not require cleaning, but carrying out will not cause any loss of quality and properties of the fitting. The exception is the situation when the welding zone was in contact with the hands of the installer during assembly. It should then be thoroughly cleaned using special PE agents.

1. Clean the pipe, cut at a right angle and remove the chips

2. Use a scraper to remove the top layer. We do this carefully, collecting only the required layer thickness. Please note that the scraper needs maintenance at least once a year. Otherwise, we can damage the surface with a blunt scraper or the action will require more effort from us

3. Clean the welding zone using a liquid for PE and tissues. Only the surface without the top layer should be cleaned

4. Clearly mark the depth to which the pipe is to be inserted. We use a marker for this, but be careful not to use it in the weld zone. Otherwise, the welding zone must be cleaned again

5. Carefully unpack the fitting

6. Adaptor wkręcamy lub wykręcamy

7. Insert the stern into the muffle until it stops, and then mark the place accordingly

We carry out the fixing operation. We will need handles or fixing devices

8. On the other side of the muff, insert the second section of the pipe

9. We re-perform the determination operation

10. We carry out the fixing operation again

We carry out the welding operation using the welding machine operating instructions

After finishing work, disconnect the wires (information about this will appear on the welding machine display

We wait until the connection cools down

11. We remove fixing devices

12. After the required time, we perform a pressure test

Break in the welding process - additional welding

If there was a break in the welding process (due to the influence of external factors), you can carry out the so-called reheating. The cause of the failure must be removed first, we do not remove the fixing devices and we do not accelerate the decline in the temperature of the fitting. It must reach the original temperature. We secure the connection point to protect against dirt and moisture during the cooling process. Now we can perform welding again, then check the seal for tightness (carry out pressure test).

- Color

- Black

- Diameter

- 32x1

- Operating pressure

- 10 bar Gas/16 bar water

- Standard

- EN1555 and EN12201

- Types

- Polyethylene (PE HD)

- Apply

- PE HD Water Supply network

Every product showcased in our online catalog comes with a standard warranty, attesting to its quality and reliability. We strive to ensure that every offer in the water and sewage sector stands as a testament to our commitment to reliability and trust for our customers.

We recognize that different projects might require specific warranty solutions. Thus, in response to individual needs, we offer the possibility to customize warranty terms. Should you wish to discuss the details of an individual warranty, we encourage you to contact us directly.

Our top priority is to give you the confidence that by choosing products from our catalog, you are opting for tried-and-true, durable solutions.

Fluctuations in raw material prices directly influence costs in the water and sewage industry. For this reason, all our quotes are made individually to reflect the current market situation.

We strive to offer our customers competitive prices while maintaining high product quality. Thanks to our individual approach to each inquiry, we provide attractive discounts and optimal purchasing conditions.

If you are interested in our offer, please contact us. We will happily prepare a quote for you, considering favorable conditions. Our flexibility ensures satisfaction with every purchase.